Military Standard, High Temperature Resistant, Oil Resistant, Heat Shrink Identification Marker Sleeves BH-AMS

- Applications: Military Standard, High Temperature Resistant, Oil Resistant, Heat Shrink Identification Marker Sleeves finds extensive applications in defence industries like aerospace, high speed rail, submarine, large vessels and architectural industry

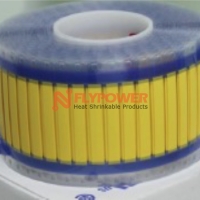

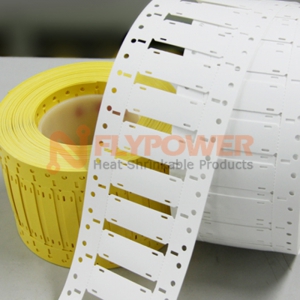

- Characteristics: Military standard, high temperature, oil resistant, heat shrink identification sleeve is made of cross-linked environmentally friendly polyolefin bombarded by high power electron beam with electronic accelerators to meet high end markets where highly reliable cable& wire identification is required. Vol Military standard, high temperature, oil resistant, heat shrink identification sleeve meets American military standard AMS-DTL-23053/6 with 2:1 and 3:1 shrink ratio available on your request. Vol Military standard high temperature oil resistant heat shrink identification sleeve boasts excellent oil resistance and is vey ideal for identifying cables and wires working in high temperature HC oil conditions, e.g JP-8 military purpose aviation kerosene. The printing fonts carry excellent rub resistance, abrasion resistance, even if washing agent or military purpose fuel oil corrosion happens, but the color code soundness still meets American military standard SAE-AS 8153 and MIL-STD-202F/215J. The choice of heat transfer printers and laser plotter controlled by computers depends on the DPI(dot per inch), printing speed and effect you require and the cost affordable to you. Identification marker sleeves are generally flattened with poriferous precision holder on both sides and a two-layer thin film to be cartridge- belt shape so that the printing process could be more automatic and precise in high speed.

-

Operating temperature range: Continuous operating temperature:-55℃~+135℃/-67℉~+275℉

Min. shrink temperature:+120℃/+248℉

Full recovery temperature:+150℃~+200℃/+302℉~+392℉

Max. storage and transportation temperature.:≤+50℃/+122℉ -

Approvals / Specifications: Meets:AMS-DTL-23053/6

NF F 00-608

Color Code Soundness:SAE-AS 81531,MIL-STD-202F/215J - Colors: Red

BH-AMS Shrink ratio-2X:

Part Number

As Supplied (mm)

After Recovery(mm)

ID(D)

Flatten Width(W2)

Double Wall Thickness

ID(d)

Single Wall Thickness

AMS-2X-1.6-

2.00±0.20

3.7±0.3

0.48±0.10

≤0.79

0.45±0.06

AMS-2X-2.4-

2.79±0.20

5.0±0.3

0.48±0.10

≤1.18

0.49±0.06

AMS-2X-3.2-

3.64±0.23

6.3±0.4

0.48±0.10

≤1.59

0.51±0.06

AMS-2X-4.8-

5.26±0.25

8.9±0.4

0.49±0.10

≤2.36

0.54±0.06

AMS-2X-6.4-

6.92±0.28

11.5±0.4

0.50±0.10

≤3.18

0.56±0.06

AMS-2X-9.5-

10.2±0.32

16.7±0.5

0.51±0.11

≤4.75

0.59±0.06

AMS-2X-12.7-

13.5±0.36

21.8±0.6

0.52±0.11

≤6.35

0.60±0.07

AMS-2X-19-

20.1±0.40

32.2±0.6

0.53±0.11

≤9.53

0.62±0.07

AMS-2X-25-

26.7±0.45

42.5±0.7

0.55±0.12

≤12.7

0.63±0.07

AMS-2X-38-

39.8±0.51

63.2±0.8

0.57±0.12

≤19.1

0.64±0.07

AMS-2X-51-

53.0±0.56

83.9±0.9

0.58±0.13

≤25.4

0.64±0.08

AMS-2X-76-

79.4±0.56

125.3±1.0

0.59±0.13

≤38.1

0.64±0.09

BH-AMS Shrink ratio-3X:

Part Number

As Supplied (mm)

After Recovery(mm)

ID(D)

Flatten Width(W2)

Double Wall Thickness

ID(d)

Single Wall Thickness

AMS-3X-1.6-

2.00±0.20

3.7±0.3

0.47±0.10

≤0.53

0.52±0.06

AMS- 3X-2.4-

2.79±0.20

5.0±0.3

0.47±0.10

≤0.79

0.57±0.06

AMS -3X-3.2-

3.64±0.23

6.3±0.4

0.48±0.10

≤1.06

0.61±0.06

AMS- 3X-4.8-

5.26±0.25

8.9±0.4

0.49±0.10

≤1.59

0.67±0.06

AMS- 3X-6.4-

6.92±0.28

11.5±0.4

0.50±0.10

≤2.36

0.71±0.06

AMS- 3X-9.5-

10.2±0.32

16.7±0.5

0.52±0.11

≤3.18

0.77±0.06

AMS- 3X-12.7-

13.5±0.36

21.8±0.6

0.53±0.11

≤4.75

0.80±0.07

AMS-3X-19-

20.1±0.40

32.2±0.6

0.55±0.11

≤6.35

0.84±0.07

AMS- 3X-25-

26.7±0.45

42.5±0.7

0.56±0.12

≤8.47

0.86±0.07

AMS- 3X-38-

39.8±0.51

63.2±0.8

0.57±0.12

≤12.9

0.89±0.07

AMS- 3X-51-

53.0±0.56

83.9±0.9

0.57±0.13

≤17.2

0.90±0.08

AMS- 3X-76-

79.4±0.56

125.3±1.0

0.57±0.13

≤25.8

0.92±0.09

Material

The sleeving shall be fabricated from irradiated, thermally stabilized and flame retarded modified polyolefin compound

Application range

Military industry; Aerospace & defense; Marine;

Operating temperature range

-55---+135℃

Minimum recovery temperature

+85℃

Maximum storage temperature

+50℃

Shrink ratio

2:1, 3:1

Color

White, Yellow, other color is available if ordered

Printing mode

Single sided printing and Double sided printing formats available

Supplied mode

Either Continuous type or Ladder format type is available

Recommended Printers

Either Thermal transfer printer or Laser printer is OK.

Recommended Ribbons

WO-80500BK resin ribbon, Black, 100mm(width)*300m(length)