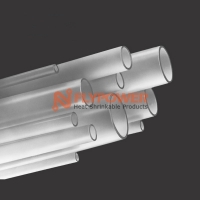

260℃ PTFE TEFLON EXTRUDED TUBING BH-PTFE(N)

- Applications: BH-PTFE(N) is manufactured with polytetrafluoroethylene (PTFE).

- Characteristics: Withstand voltage : 150V-600V,Specially designed for applications where very high temperature and chemicals resistant extreme electrical insulation an highly flame retardant are required such as in the field of automotive , military and aerospace.

-

Operating temperature range: Operating temperature: -65℃ to +260℃

Smelting point: 327℃ - Approvals / Specifications: Meet: SAE-AMS-DTL-23053/12

- Colors: Black, Transparent

|

(AWG) |

Inside diameter ID(mm) |

Outside DiameterOD(mm) |

Package(M/Spool) |

||

|

S |

T |

L |

|||

|

30 |

0.30±0.10 |

0.80±0.10 |

0.70±0.10 |

0.60±0.10 |

305 |

|

28 |

0.38±0.10 |

0.88±0.10 |

0.78±0.10 |

0.68±0.10 |

305 |

|

26 |

0.46±0.10 |

0.96±0.10 |

0.86±0.10 |

0.76±0.10 |

305 |

|

24 |

0.56±0.10 |

1.16±0.10 |

1.06±0.10 |

0.86±0.10 |

305 |

|

23 |

0.66±0.10 |

1.26±0.10 |

1.16±0.10 |

0.96±0.10 |

305 |

|

22 |

0.71±0.10 |

1.31±0.10 |

1.21±0.10 |

1.01±0.10 |

305 |

|

21 |

0.81±0.10 |

1.41±0.10 |

1.31±0.10 |

1.11±0.10 |

305 |

|

20 |

0.86±0.10 |

1.66±0.10 |

1.46±0.10 |

1.16±0.10 |

305 |

|

19 |

0.96±0.20 |

1.76±0.20 |

1.56±0.20 |

1.26±0.20 |

200 |

|

18 |

1.07±0.20 |

1.87±0.20 |

1.67±0.20 |

1.37±0.20 |

200 |

|

17 |

1.19±0.20 |

1.99±0.20 |

1.79±0.20 |

1.49±0.20 |

200 |

|

16 |

1.34±0.20 |

2.14±0.20 |

1.94±0.20 |

1.64±0.20 |

153 |

|

15 |

1.50±0.20 |

2.30±0.20 |

2.10±0.20 |

1.80±0.20 |

153 |

|

14 |

1.68±0.20 |

2.48±0.20 |

2.28±0.20 |

2.00±0.20 |

100 |

|

13 |

1.93±0.20 |

2.73±0.20 |

2.53±0.20 |

2.25±0.20 |

100 |

|

12 |

2.16±0.25 |

2.96±0.25 |

2.76±0.25 |

2.50±0.25 |

100 |

|

11 |

2.41±0.25 |

3.21±0.25 |

3.01±0.25 |

2.76±0.25 |

150 |

|

10 |

2.69±0.25 |

3.49±0.25 |

3.29±0.25 |

3.04±0.25 |

150 |

|

9 |

3.00±0.25 |

4.00±0.25 |

3.80±0.25 |

3.40±0.25 |

150 |

|

8 |

3.38±0.25 |

4.38±0.25 |

4.18±0.25 |

3.78±0.25 |

100 |

|

7 |

3.76±0.25 |

4.76±0.25 |

4.56±0.25 |

4.16±0.25 |

100 |

|

6 |

4.22±0.25 |

5.22±0.25 |

5.02±0.25 |

4.72±0.25 |

100 |

|

5 |

4.72±0.25 |

5.72±0.25 |

5.52±0.25 |

5.20±0.25 |

50 |

|

4 |

5.28±0.30 |

6.28±0.30 |

6.08±0.30 |

5.88±0.25 |

50 |

|

3 |

5.94±0.30 |

6.94±0.30 |

6.74±0.30 |

6.54±0.25 |

1 |

|

2 |

6.68±0.30 |

7.68±0.30 |

7.48±0.30 |

7.28±0.25 |

1 |

|

1 |

7.46±0.30 |

8.46±0.30 |

8.26±0.30 |

8.06±0.25 |

1 |

|

0 |

8.38±0.30 |

9.38±0.30 |

9.18±0.30 |

8.98±0.25 |

1 |

|

Property |

Test Method |

Typical Data |

|

Tensile strength |

ASTM D 2671 |

≥34.5 MPa |

|

Elongation at break |

ASTM D 2671 |

≥150% |

|

Specific gravity |

ASTM D 792 |

2.30 |

|

Heat shock |

ASTM D 2671 (400℃, 4 hrs) |

No cracking or dropping |

|

Cold bend |

ASTM D 2671 (-65℃, 4 hrs) |

No cracking |

|

Flammability |

ASTM D 2671 |

Self extinguish |

|

Volume resistance |

ASTM D 2671 |

≥1018Ω.cm |

|

Dielectric strength |

ASTM D 2671 |

≥34KV/mm |

|

Copper corrosion |

UL 224 |

Pass |

|

Fluid resistance |

SAE-AMS-DTL-23053/12 |

Excellent |

|

Water absorption |

ASTM D 570 |

0.1 Max. |