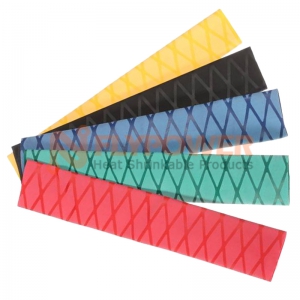

DUAL WALL ADHESIVE-LINED POLYOLEFIN TUBING FOR AUTOMOTIVE PIPE PROTECTION BH-5(2000)

- Applications: BH-5(2000) specially designed for protection of automotive metal pipes and fuel lines against environment damages

- Characteristics: This dual wall frame can effectively protect the pipes against any kinds of damages caused by vibration, friction , corrosion and thus improvethe reliability of these pipes.

-

Operating temperature range: Minimum fully recovery temperature: 120℃

Operating temperature: -55℃ to + 135℃ - Approvals / Specifications: CE

- Colors: Black

|

Normal size(mm) |

Standard pipe diameter |

As supplied(mm) |

After recovered(mm) |

Standard length(m) |

|||

|

(inch) |

(mm) |

Inside diameter(min.) |

Inside diameter(Max.) |

Wall thickness(mm) |

Adhesive Thickness(mm) |

||

|

BH-5(2000)-5 |

1/8 |

3.50 |

5.50 |

3.30 |

1.00 |

0.20 |

200 |

|

BH-5(2000)-6 |

3/16 |

4.76 |

6.50 |

4.60 |

1.00 |

0.20 |

200 |

|

BH-5(2000)-8 |

1/4 |

6.35 |

8.50 |

6.00 |

1.00 |

0.20 |

100 |

|

BH-5(2000)-10 |

5/16 |

8.00 |

11.50 |

7.00 |

1.00 |

0.20 |

100 |

|

BH-5(2000)-15 |

3/8 |

10.00 |

15.00 |

9.50 |

1.00 |

0.20 |

100 |

Special size, cut pieces are available on request.

| Property | Test Method | Typical Data |

| Operating temperature | IEC 216 | -55 to +105℃ |

| Longitudinal shrinkage | UL 224 | 0 to -10% |

| Eccentricity | ASTM D 2671 | ≤30% |

| Tensile strength | ASTM D 2671 | 12MPa(min) |

| Elongation at break | ASTM D 2671 | 300%(min) |

| Heat ageing Tensile strength Ultimate elongation |

after 24hrs. at 120℃ | 12Mpa(min) 270%(min) |

| Deformation resistance | 50%(min) | |

| Impact resistance | ASTMD 746 | No cracking at -35℃ |

| Drop impact resistance | No cracking | |

| Cold resistance | ASTM D 746 ( -35℃, 1hr) | No cracking |

| Stress cracking resistance | ASTM D 1693 (50℃,24hrs.) | No cracking |

| Fluid resistance | ASTM D 2671 25℃,72hrs. Brake fluid (Honda) Unleaded petrol |

Tensile strength 12Mpa(min) Ultimate elongation 300%(min) Tensile strength 7.8MPa(min) Ultimate elongation 150%(min) |