Medical grade peelable heat shrink tubing BH-2(PMT)-LS

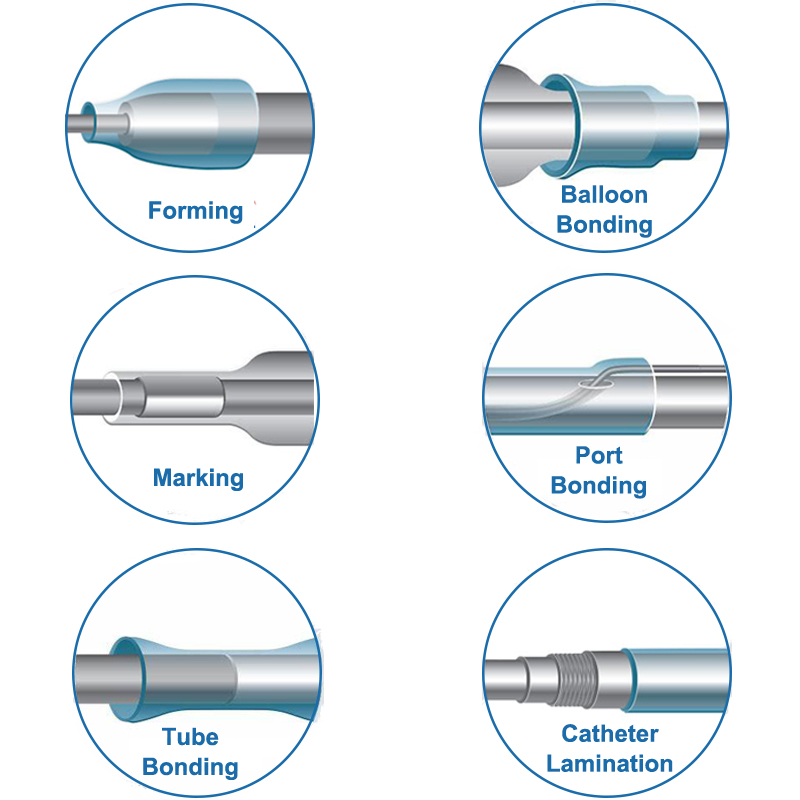

- Applications: Widely using for catheter lamination, balloon tacking, tube bonding and tube forming. Also well-suited for laser-welding operations of stents and balloons.

- Characteristics: BH-2(PMT)-LS is made by medical grade modified polyolefin, it can be directly and easily peeled the heat shrink tube away from the recovered shaft without additional heat.

-

Operating temperature range: Minimum shrink temperature: 70℃

Fully recovery temperature: +130℃~ +250℃

Special design it could withstand Max. 250℃ in the recovery process

Operating temperature: -45℃~+105℃ - Approvals / Specifications: Meet: RoHS

- Colors: Transparent

|

Model |

Size (mm) |

As Supplied (mm) |

After Full Recovered(mm) |

|

|

Max. ID (D) |

Wall Thickness(T) |

|||

|

BH-2(PMT)-LS-0.6 |

0.60 |

0.71±0.10 |

0.28 |

0.25±0.05 |

|

BH-2(PMT)-LS-0.8 |

0.80 |

1.02±0.13 |

0.36 |

0.28±0.05 |

|

BH-2(PMT)-LS-1.2 |

1.20 |

1.40±0.13 |

0.51 |

0.41±0.08 |

|

BH-2(PMT)-LS-1.6 |

1.60 |

1.83±0.13 |

0.71 |

0.51±0.08 |

|

BH-2(PMT)-LS-2.4 |

2.40 |

2.72±0.20 |

1.04 |

0.51±0.08 |

|

BH-2(PMT)-LS-3.2 |

3.20 |

3.56±0.25 |

1.45 |

0.51±0.08 |

|

BH-2(PMT)-LS-4.8 |

4.80 |

5.21±0.25 |

2.21 |

0.51±0.08 |

|

BH-2(PMT)-LS-6.4 |

6.40 |

6.99±0.38 |

3.00 |

0.64±0.08 |

|

BH-2(PMT)-LS-9.5 |

9.50 |

10.54±0.51 |

4.30 |

0.64±0.08 |

Customized dimensions and heat shrink ratio for your special applications on request.

Cross Reference : Tyco-Raychem MT-LWA, Junkosha FEP-PHST and Zeus FluoroPEELZ™

|

Property |

Test Method |

Typical Data |

|

Longitudinal change |

ASTM D 2671 |

-10%~10% |

|

Concentricity as supplied |

ASTM D 2671 |

≥ 70% |

|

Tensile strength |

ASTM D 2671,20"/minute |

≥ 1500 Mpa |

|

Elongation at break |

ASTM D 2671,20"/minute |

200% minimum |

|

Secant modulus (expanded) |

ASTM D 2671 |

≤ 2.5 x104 Mpa |

|

Elongation at break after aging |

ASTM D 2671(175˚C/168 hrs) |

≥ 100% |

|

Electrical dielectric strength |

ASTM D 2671 |

≥ 500 volts/mm |

|

Dielectric withstand |

ASTM D 2671(AC3000V/60Hz) |

60 Seconds no breakdown |

|

Heavy metals analysis |

USP XXII Physiochemical tests-plastic |

≤ 1 ppm(total of all metals) |