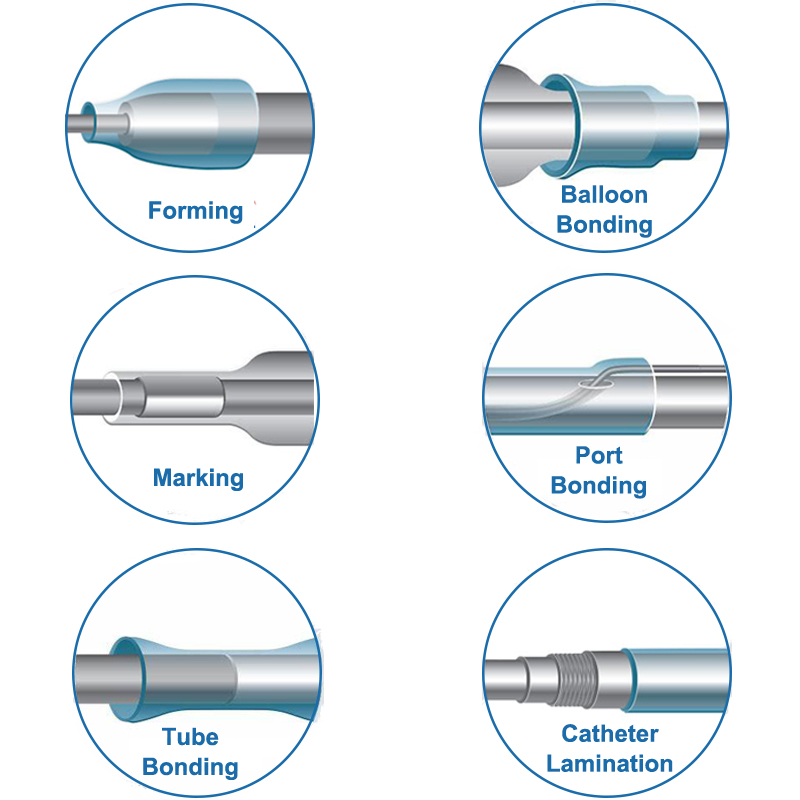

Medical grade linear fluorinated polymer heat shrink tubing for process aid applications BH-MT-FEP-PL

- Applications: It is suitable for the production of various medical multi-layer catheters and the welding rheological process of balloons and joints, etc.

- Characteristics: BH-MT-FEP-PL is made of medical-grade fluorinated polymer. After heat shrinking, it can be quickly and completely peeled off from the outer layer of the catheter without using cutting tools and without sticking.

-

Operating temperature range: Shrink Ratio: 1.3:1/1.6:1

Minimum shrink temperature: 190℃

Fully recovery temperature: 260℃

High transparency, easy to observe welding conditions

Excellent linear tensile strength

Excellent axial tear propagation -

Approvals / Specifications: Meet: RoHS

ISO 10993-1 compliant - Colors: Transparent

|

Model |

Expanded ID (Min.) |

Fully recovered ID (Max.) |

Fully recovered wall thickness |

Standard Length |

||||||

|

1.3:1 |

1.6:1 |

|||||||||

|

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Inch |

M |

|

|

BH-MT-FEP-PL-0.8 |

0.031 |

0.8 |

0.024 |

0.62 |

0.02 |

0.50 |

0.008±0.002 |

0.20±0.05 |

48.0 |

1.22 |

|

BH-MT-FEP-PL-1.2 |

0.047 |

1.2 |

0.036 |

0.92 |

0.03 |

0.75 |

0.008±0.002 |

0.20±0.05 |

48.0 |

1.22 |

|

BH-MT-FEP-PL-1.4 |

0.055 |

1.4 |

0.043 |

1.08 |

0.035 |

0.88 |

0.008±0.002 |

0.20±0.05 |

48.0 |

1.22 |

|

BH-MT-FEP-PL-1.6 |

0.063 |

1.6 |

0.048 |

1.23 |

0.039 |

1.00 |

0.008±0.002 |

0.20±0.05 |

48.0 |

1.22 |

|

BH-MT-FEP-PL-2.4 |

0.094 |

2.4 |

0.073 |

1.85 |

0.059 |

1.50 |

0.008±0.002 |

0.20±0.05 |

48.0 |

1.22 |

|

BH-MT-FEP-PL-3.2 |

0.126 |

3.2 |

0.097 |

2.46 |

0.079 |

2.00 |

0.008±0.002 |

0.20±0.05 |

48.0 |

1.22 |

|

BH-MT-FEP-PL-4.8 |

0.189 |

4.8 |

0.145 |

3.69 |

0.118 |

3.00 |

0.010±0.002 |

0.25±0.05 |

48.0 |

1.22 |

|

BH-MT-FEP-PL-6.4 |

0.252 |

6.4 |

0.194 |

4.92 |

0.157 |

4.00 |

0.010±0.002 |

0.25±0.05 |

48.0 |

1.22 |

Customized dimensions and heat shrink ratio for your special applications on request.

Cross Reference : Junkosha FEP-PHST and Zeus FluoroPEELZ™

|

Property |

Test Method |

Typical Data |

|

Longitudinal change |

ASTM D2671 |

0%~15% |

|

Tensile strength |

ASTM D2671 |

≥10.3MPa |

|

Elongation at break |

ASTM D2671 |

≥200% |

|

Heat resistance |

260˚C/4hrs |

No cracking and fading |